Enzymes are bio-catalysts that help in accomplishing chemical reactions at benign conditions; not requiring toxic chemicals or elevated temperature and pressure conditions. Enzymes are made up of a combination of 20 naturally occurring amino-acids connected to each other like beads on a necklace. Indeed, our human body has about 75000 enzymes, which aid in metabolism and digestion. Similarly, organisms such as Bacteria, Yeast, Fungi have a myriad set of enzymes assisting their functions.

In the industry, enzymes have found several applications — in poultry, agriculture, textiles, & synthesis of active pharmaceutical ingredients (API)s. Often the wild-type (WT) enzyme isolated from an organism is designed to work on its native substrate under physiological conditions. For industrial purposes the substrate to be converted is a non-native molecule of commercial interest, and also the reaction may be required with varied pH or temperature conditions. The great challenge then is to “tweak” the enzyme to efficiently convert the non-native substrate to the desired product. This is where enzyme engineering comes into the picture, where the chemical composition of the enzyme, i.e. its amino-acid sequence is modified to increase its efficiency to accomplish the desired reaction. But how can we do that?

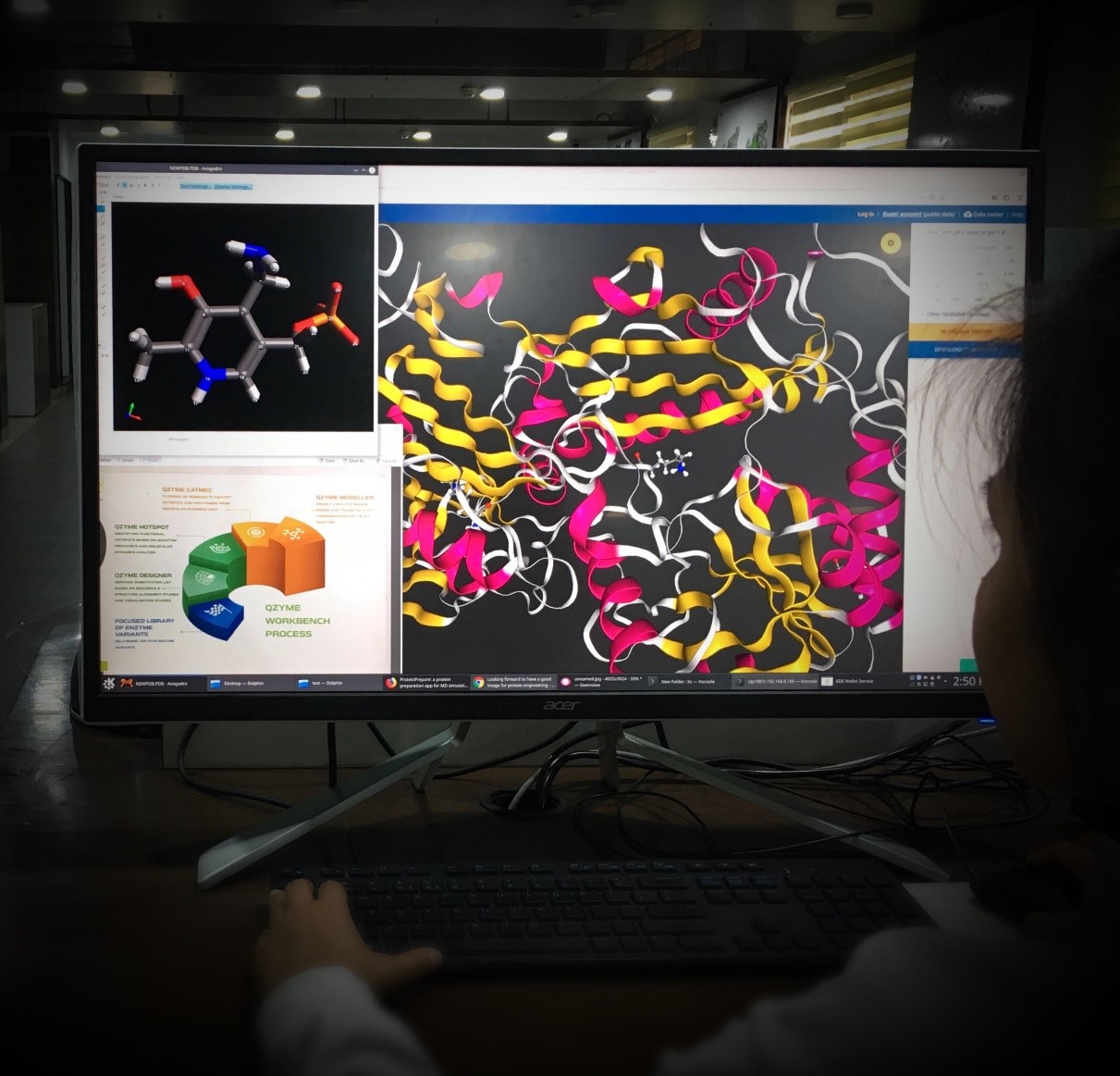

We now ZOOM IN to the depths of molecular structure and dynamics for enzyme engineering. Welcome to the world of Quantumzyme! At Quantumzyme, our computational protocol called QZyme WorkBench™ is used to generate the designed variants of enzymes for the desired reaction on the specific substrate.

A host of computational chemistry methods developed by Prof. Martin Karplus, Michael Levitt and Arieh Warshel (awarded Nobel Prize in Chemistry 2013) such as Molecular Dynamics simulation, Quantum Mechanics are used to study the enzymatic reaction at the molecular level; and screen hundreds of enzyme variants on the computer for analysis of the parameters affecting the reaction. These parameters could be substrate binding energies, transition state energies, etc. to name a few. At the end of the protocol, the top 5 to 10 enzyme variants are generated, predicted to have increased activity and specificity for the reaction. The computational approach saves both time and cost, compared to traditional laboratory approaches such as site-directed mutagenesis, as these experiments have to be done on all the possible enzyme variants, and with random modification, the possible list of variants to be screened in the laboratory is huge. The Nobel Prize in Chemistry 2018 was awarded to three eminent scientists — Frances Arnold, George Smith and Sir Gregory Winter, for the directed evolution of enzymes. Quantumzyme’s computational rational design approach using the knowledge of the enzyme structure and dynamics gives more leads and insights, as compared to random mutations. The final down-selected enzyme variants from Quantumzyme are then validated in the laboratory by our customer or partner organizations. As enzymatic processes are the first choice to keep our environment clean, the demand for new industrial enzymes and processes are on the increase.

So…….. Let us invent new enzymes & GO GREEN!!! 🍃