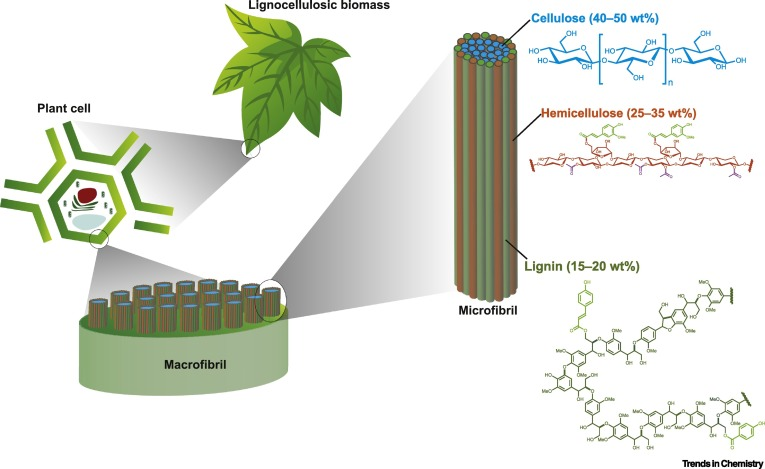

Lignin being a robust material, is considered as useless due to its inhibitory effect on microbes because it acts as a physical barrier for cellulose degradation. Hence to produce high-value materials, it has been removed from cellulosic biomass. However, lignin monomers can be converted to value-added chemicals such as biodegradable plastics and food additives which simply proves the facts that “One man’s garbage is another man’s gold”, it’s just person’s perspective to consider it as gold or garbage. Lignin/Starch plays a vital role for industries like paper, pulp, textile and petrochemical where hydrolysis of starch is achieved by acid pre-treatment. It was reported by Dziedzic and Kearsley (2012), acid hydrolysis was discovered at the beginning of the 19th century when a German chemist, Kirchoff showed that by boiling wheat starch with dilute sulfuric acid, a sweet syrup could be obtained. Later, potato starch was used as the starch source and sulfuric acid was replaced by hydrochloric acid and indirect heating of the reaction vessel. Since then, acid has been used to a great extent for the breakdown of starch into glucose. Due to cost effectivity and ease of availability acid hydrolysis is used for starch hydrolysis. As it says every coin has two sides, this method has its advantages but it also has its disadvantages which causes relatively low yield and formation of undesirable by-products (Ramprakash and Muthukumar 2014). Furthermore, the process has poor flexibility since the end product can only be changed by change in the degree of hydrolysis and the equipment used must be capable of withstanding acid at the temperature of 140-150°C. The most complicated part will be removal of undesirable by-products such as furan (Klinke et al., 2004), if the product of hydrolysis is intended for further usage (i.e., substrate for the fermentation process). To overcome these disadvantages and opt for more environmentally friendly method, Enzymatic hydrolysis of starch used in which a biological agent(enzyme) is used in pre-treatment which utilizes mild pressure and/or temperature. As it is more environmentally viable approach it does not involve any toxic acid, alkali, or any reactive species, pre-treatment inhibitors, need for chemical recovery.

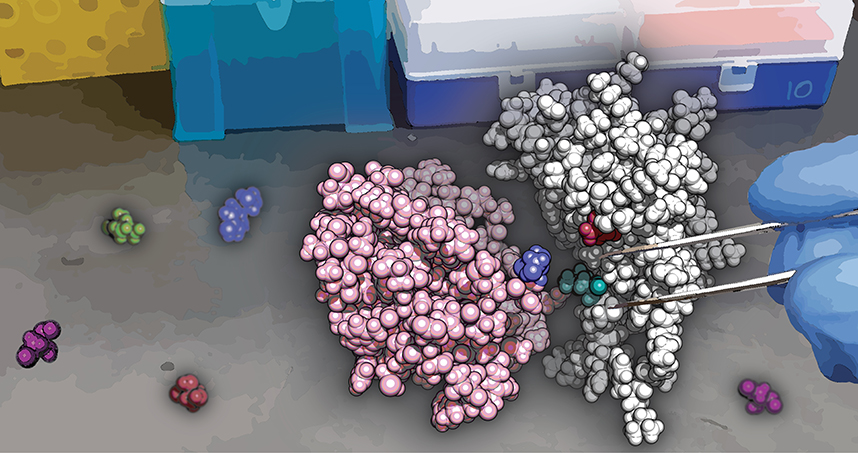

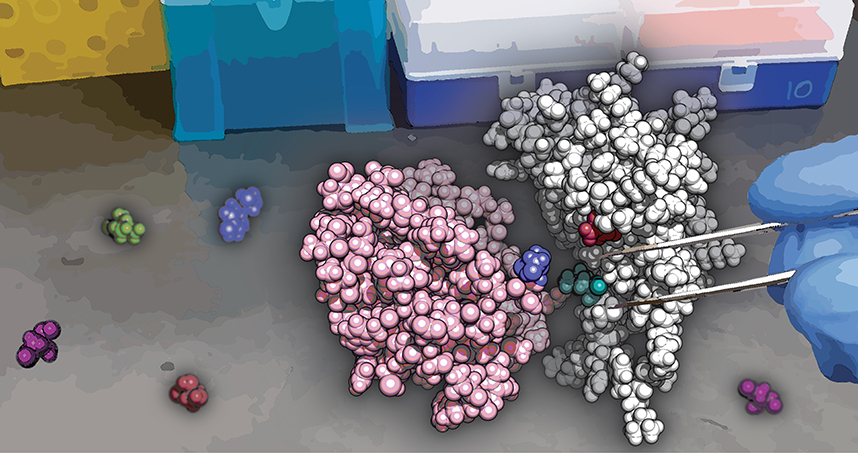

Moving forward with environmentally viable approach, Lignin degradation is carried out through peroxidase, laccase and other proteins with auxiliary activity which is the first step in lignin valorisation. Metabolic engineering of microorganisms for increased tolerance and production yield is the second step for lignin valorisation. Laccases (benzenediol: oxygen oxidoreductases, EC 1.10.3.2) being blue multicopper oxidases (Giardina and Faraco 2010) belonging to diverse sources such as bacteria, fungi and plants catalyses the oxidation of an array of aromatic substrates concomitantly with the reduction of molecular oxygen to water. It belongs to class of enzymes, which have innate properties of reactive radical production. Huge amount of waste is released by Textile, pulp and paper industries in the environment and this causes a greater concern to the environment. Attention has been increased on the discover of enzymes which can help us resolve these problems. Enzymes are biological catalysts that help to accelerate chemical reactions and without it, the reactions would take place at a considerably slower rate. Unlike chemical catalyst, they are highly selective and specifically catalyse specific reaction. Basically, laccase uses molecular oxygen to produce water as by-product where it can degrade a range of compounds including phenolic and non-phenolic compounds.

This unique feature of laccase to act on a range of substrates to detoxify a range of pollutants have made them to be usable for several purposes in many industries makes it an ideal candidate to use as an alternative to already existing chemical methods. Laccases are ancient enzymes with a promising future. This class of enzymes still remains of great relevance both as a model for invitro/in vivo relationships and as a green tool in many processes of the biotechnology industries in the near future.

With a few tweaks in the enzyme structure and function activity using computational resource, an enzyme can be used to enhance its activity to the fullest. In the past few decades, a tremendous revolution in computational protein engineering has helped protein manipulation in overcoming the barriers involved in enzyme engineering. Here we want to highlight though efficient cheaper chemical methods are available for degradation of lignin, an environmentally friendly enzyme is already available in nature which needs to be explored. With help of computational bio catalysis, it can be improved to its fullest and we can lead to cleaner and greener future.

References

- Giardina, Paola, and Vincenza Faraco. 2010. “Laccases: A Never-Ending Story.” : 369–85.

- Ramprakash, Balasubramani, and Karuppan Muthukumar. 2014. “Comparative Study on the Production of Biohydrogen from Rice Mill Wastewater.”

- International Journal of Hydrogen Energy 39(27): 14613–21. http://dx.doi.org/10.1016/j.ijhydene.2014.06.029.